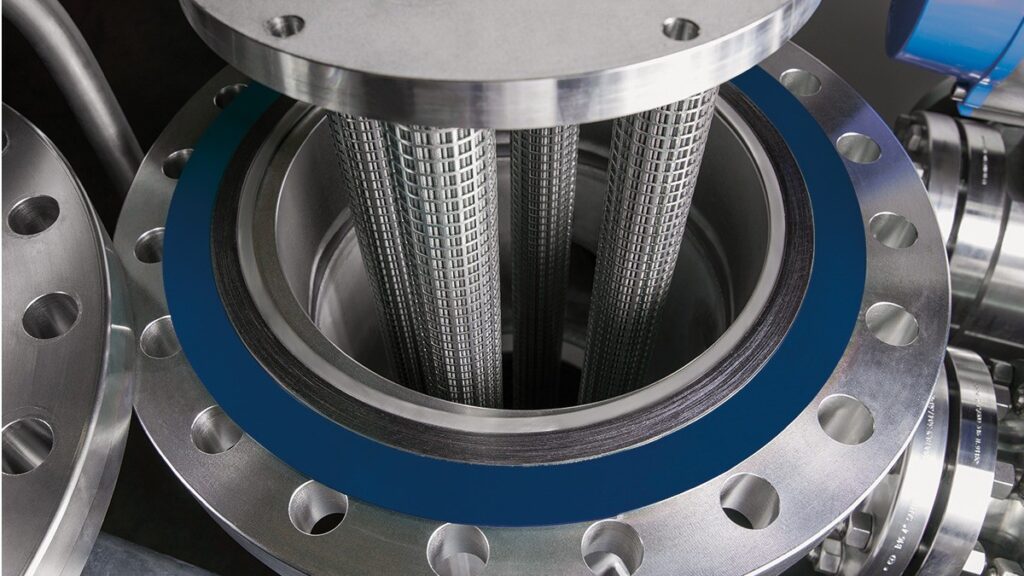

PACO’s origin and core competence lie in the manufacture of highly precise metal wire meshes. In the company’s own weaving mill, meshes are produced from a wide variety of materials and wire diameters, with widths of up to 3.2 meters. Whether standard or custom-made meshes, PACO offers one of the most extensive product portfolios on the market — flexibly manufactured, often available from stock, and tested to the highest quality standards.

The mesh range includes a broad variety of weave types, mesh openings, and wire diameters. Meshes are manufactured, among others, from stainless steel (e.g. 1.4301, 1.4401, 1.4571), copper, brass, nickel, and aluminum, as well as high-performance alloys such as Inconel or Hastelloy. Special materials such as platinum or silver, as well as composite wires consisting of metal with a plastic coating, are also among the materials used.

All wires undergo intensive incoming inspection. State-of-the-art inline measurement technology such as the MeshInspector, along with internal and external testing standards (DIN EN ISO 9044, DIN EN ISO 3310, among others), ensure consistently highest mesh quality — for excellent filtration and screening results in a wide range of applications.

PACO combines materials expertise with decades of application experience and also provides support with tests and trials—either in its own technical center or directly on the customer’s premises.