Maintenance processes usually also require cleaning processes, both for machines, systems and infrastructure as well as in the preparation of assemblies and spare parts. Although cleaning steps in maintenance require a considerable amount of time, personnel and resources, little attention is often paid to their optimization or innovative alternatives, as cleaning know-how in maintenance is hardly available due to a lack of training opportunities.

Sustainable Clean therefore takes this into account as a concept:

– Planning of cleaning processes

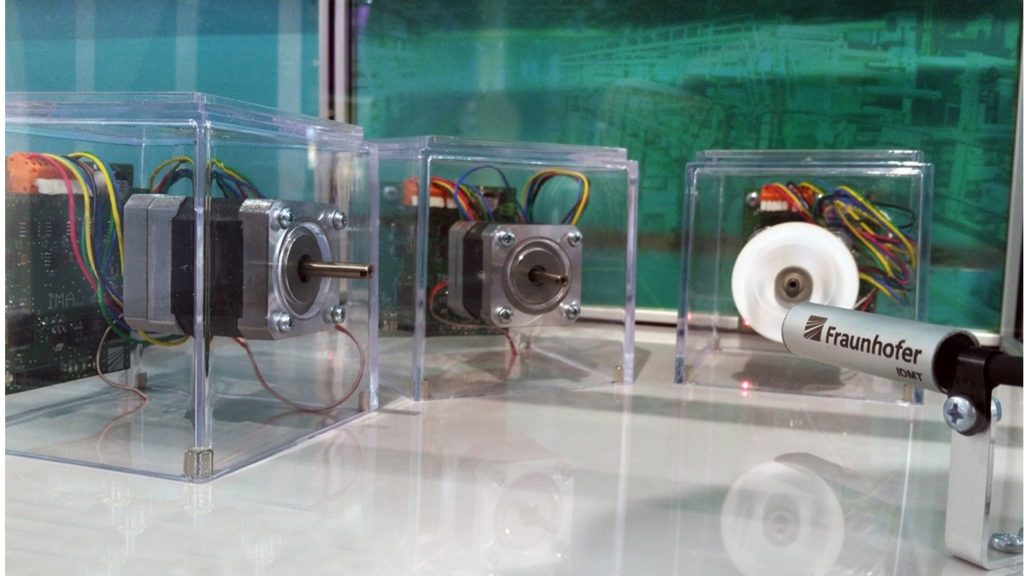

– Technology development for customer-specific applications

– Quality assurance and process monitoring

– Analysis and sensor technology for contamination

– Damage analysis and root cause analysis

– Optimization with regard to resource and energy efficiency

– Sustainability balancing

– Practice-oriented training formats

Your contact at the stand:

Frank-Holm Rögner

Fraunhofer FEP