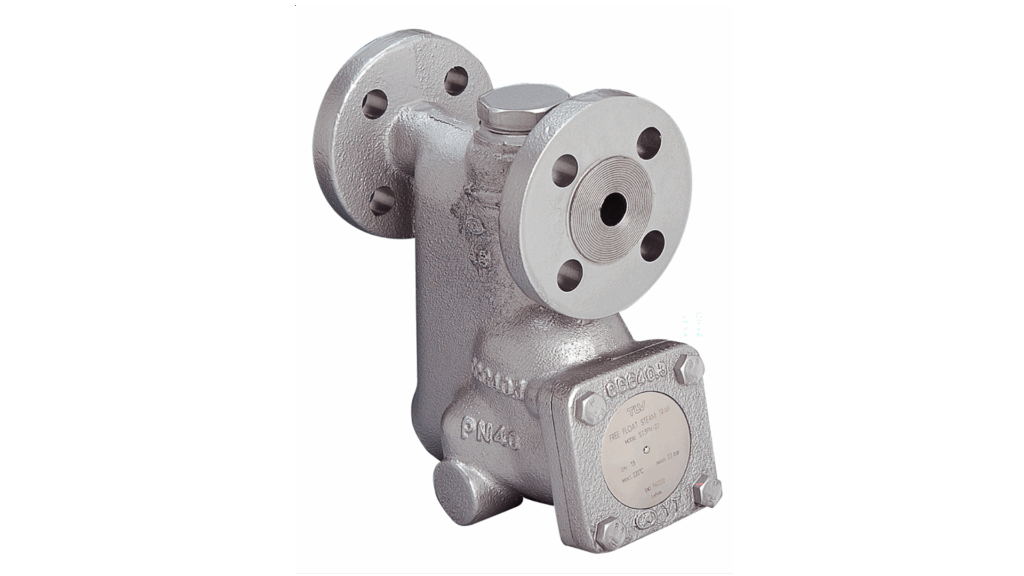

Compact, reliable steam trap station for steam mains, tracers, and light processes. QuickStation® enables condensate drainage from a wide range of applications, and inline replacement of universal flange steam traps in minutes.

Simple trap selection and installation

– Steam traps can be installed in minutes, minimizing production downtime and with TLV’s range of precision-engineered steam traps, allowing your process equipment to perform at optimal conditions.

– By making trap installation, replacement, and maintenance simple, costly steam trap problems can be rectified quickly, preventing energy loss and improving energy efficiency.

Compact, reliable, all-in-one design

– QuickStation® is of stainless steel construction for durability and corrosion resistance.

– Each QuickStation® includes isolation valves, an integral strainer to help prevent equipment damage or production issues due to entrained material, and a check valve to prevent backflow.

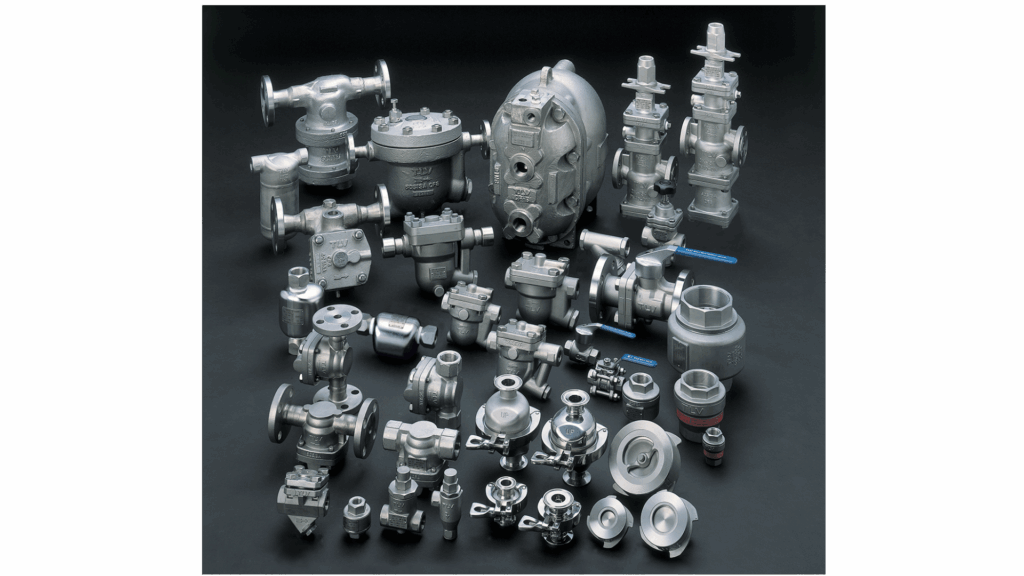

Compatible with the ideal steam trap for your application

QuickStation® is compatible with various steam trap units for condensate drainage from a wide range of applications, including light process use, tracers and steam mains.

Flexible configuration for maximum reliability

QuickStation® is available with either single or double upstream/downstream isolation valves and multiple piping arrangements.

Optional blowdown valve

Elbow-type BD2 blowdown valve available for safer condensate blowdown and scale removal.

Application Areas

– Simplifying installation and maintenance of steam trap and peripheral equipment.

– Suitable for use where ease of steam trap installation and maintenance is critical, such as the pharmaceutical, food, and beverage industries, and for institutional use.