Real-time prediction of the system status based on functional parameters during operation. This prevents critical system states and downtimes. The status evaluation also enables new business models such as the second use of components and assemblies.

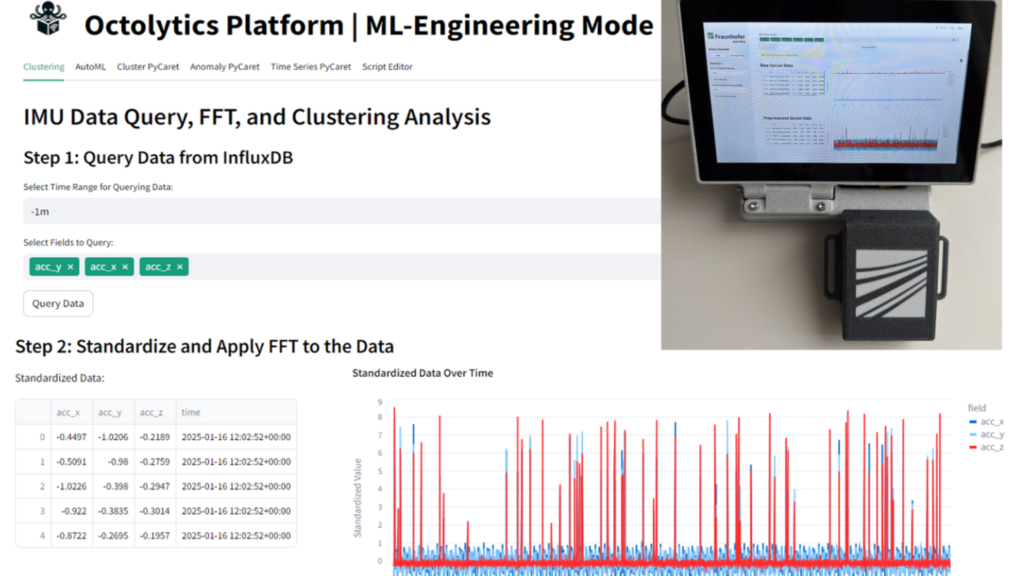

Description of the implementation:

– Combination of classic failure models and machine learning methods (AI) for reliability prediction (grey box modeling)

– Resource-efficient implementation with standardized interfaces such as FMI and OPC UA

– Universal system modeling that does not require additional sensors

Derived offer for the industry:

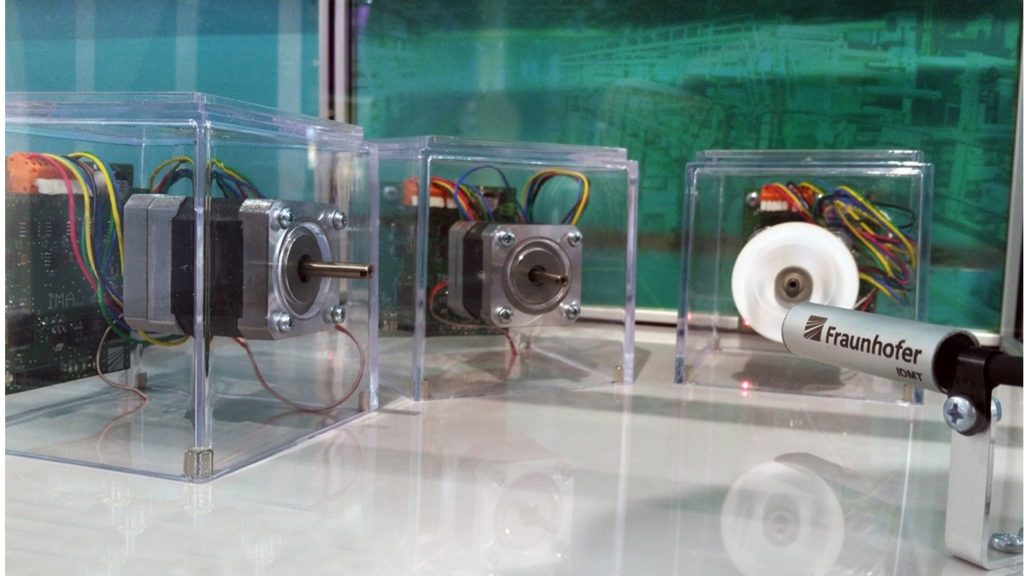

– Resource-efficient strategies for assessing the condition and remaining service life during operation

– Digital, data-based fingerprint for detecting age-related wear and tampering

– Trustworthy compact models (system, degradation models) for integration into digital twins

– Remaining service life as a decision criterion for: Reuse / reprocessing / recycling

Your contacts at the stand:

Dr. Andreas Middendorf | (Dr. Johannes Jaeschke)

Fraunhofer IZM