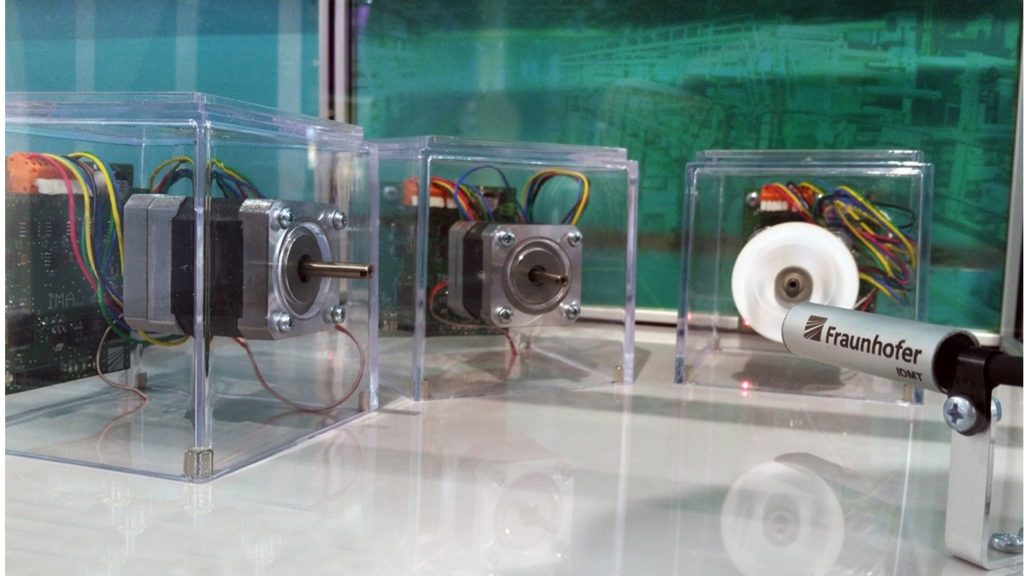

We demonstrate image-based quality monitoring, sensor or model-based condition monitoring and predictive maintenance using the example of a miniaturized drive train to show interactively how machine conditions can change in different load scenarios and still be monitored.

Monitoring quality: Using imaging techniques, we demonstrate the integration of quality control into condition monitoring in order to detect quality defects at an early stage so that avoidable rejects can be reduced. (Generative AI for maintenance support and optimization for simulative generation of damage patterns, predictive and prescriptive maintenance for predicting quality losses and recommendations for action as assistance systems).

Monitoring drive shafts: With the magnetostrictive sensor, we demonstrate how torsion and speed can also be integrated into condition monitoring retrospectively in typical drive trains. The software enables the detection of dynamic and static torsional loads (sensor technology for condition monitoring and energy monitoring, data analysis, evaluation and visualization using KPIs).

Predictive maintenance: We present how to build step-by-step AI models in order to use mathematical methods to record the wear stock of machines and predict it, taking into account utilization (sensor technology for condition monitoring and energy monitoring).

Your contact at the stand:

Dr. Benjamin Adrian

Fraunhofer ITWM