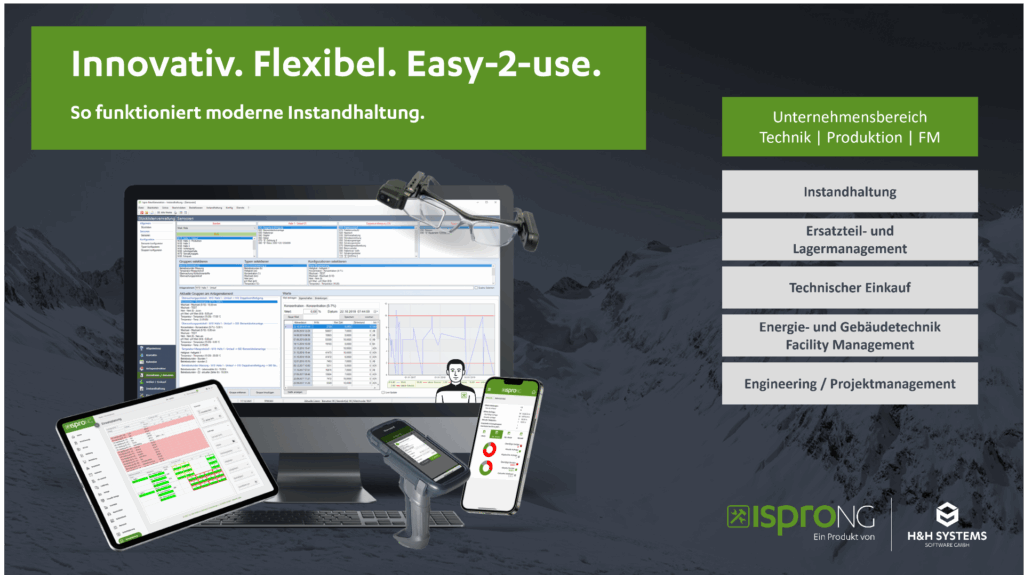

With the ispro [NextGeneration] maintenance software, modern, future-proof maintenance and asset management is achieved. T

hrough continuous development and the targeted use of the latest technologies, we simplify the daily work of maintenance personnel.

A selection of the technical highlights:

+ The AI assistant "Commander Data" analyzes, anticipates, and optimizes. Sensor values and historical data are evaluated, error probabilities are calculated, and procedural suggestions for defect rectification are generated. Automatically generated maintenance orders and reports ensure even more efficient processes.

+ Industry 4.0 (sensors, OPC, predictive maintenance): Sensor endpoints are created and linked to isproNG. Values can be retrieved from the OPC server at specific intervals and displayed graphically, for example. An alarm is triggered if a corresponding limit is exceeded. Unplanned production downtime is reduced, and maintenance intervals are dynamically adjusted.

+ Supplier webshop integration (OCI interface): The OCI interface enables the direct transfer of spare parts purchased in the webshop to the isproNG spare parts management system. This eliminates the need for additional data entry, and you have continuous access to up-to-date prices and product information.

+ Smart Glasses / Field Support: With the smart glasses, you can scan barcodes and QR codes and view live system data. You immediately gain an overview of measurement data and wear values, as well as checklists for inspection and maintenance. The Field Support module allows on-site technicians to transmit their camera image in real time to internal experts, who can provide targeted support through direct annotations and comments within the image.