JESSBERGER drum pumps are versatile vertical centrifugal pumps, ideal for transferring a wide range of media.

Available pump tube materials and temperature limits:

Polypropylene pump tubes: For low-viscosity media such as acids, alkalis, and cleaning agents, up to 50 °C

PVDF pump tubes: For highly aggressive chemicals, up to 90 °C

Aluminium pump tubes: For mineral oil-based media up to 1,000 mPas, up to 90 °C

Stainless steel pump tubes: For flammable liquids and food products, up to 90 °C (with ECTFE rotor) or 120 °C (with stainless steel rotor)

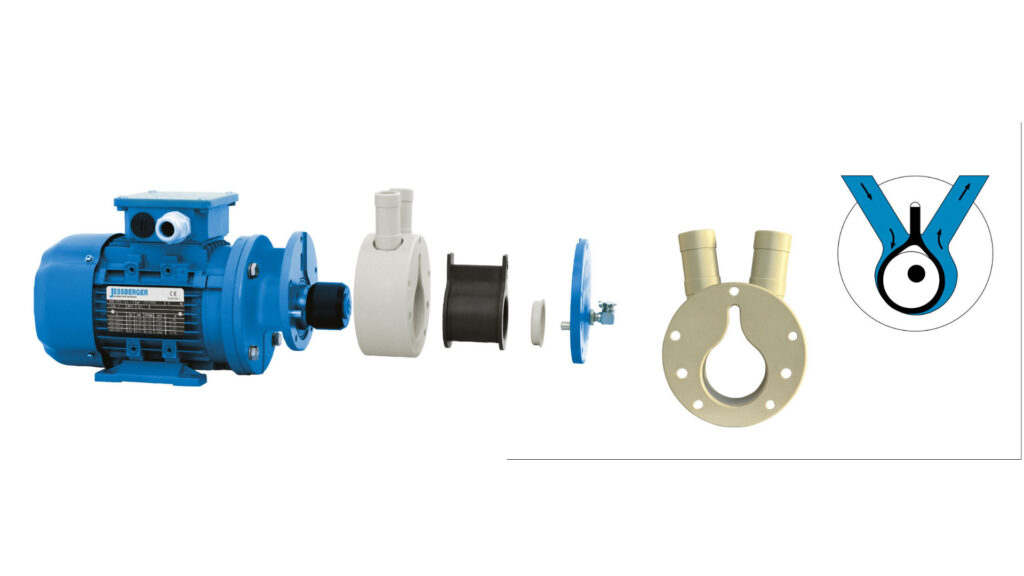

Operating principle:

The drum pump consists of a motor (electric or pneumatic) and an immersion tube. At the lower end, an impeller rotates at 10,000–12,500 rpm. The immersion tubes are modular and can be connected to any drum pump motor without tools (except in ATEX zones).

Custom configuration:

To recommend the most suitable pump, JESSBERGER requires details such as the pumped medium, concentration, viscosity, temperature, presence of particles, required flow rate, container size, operating time, and any additional application-specific requirements.

Advantages of JESSBERGER drum pumps:

Quality “Made in Germany”

Direct from the manufacturer

Short delivery times (mostly in stock)

Excellent price-performance ratio (savings of 20–50%)

Family-owned company with direct contact to the owners

High flexibility thanks to a small, specialized team

Fast and competent support and consultation in all matters