In order to meet the increasing demands in production with regard to maximum flexibility and efficiency, more and more companies are striving for a close connection between automation and computer technology. This is accompanied by an intensive exchange of data, including production and qualification data as well as data from condition monitoring systems. This data contains valuable information about the production process, product quality and the wear and tear of components on machines and systems. With efficient structuring, self-learning systems and innovative big data and AI approaches, these potentials can be turned into strategic competitive advantages. We support you in this and offer you a comprehensive portfolio ranging from condition monitoring and predictive maintenance to quality assurance aspects in industrial production processes.

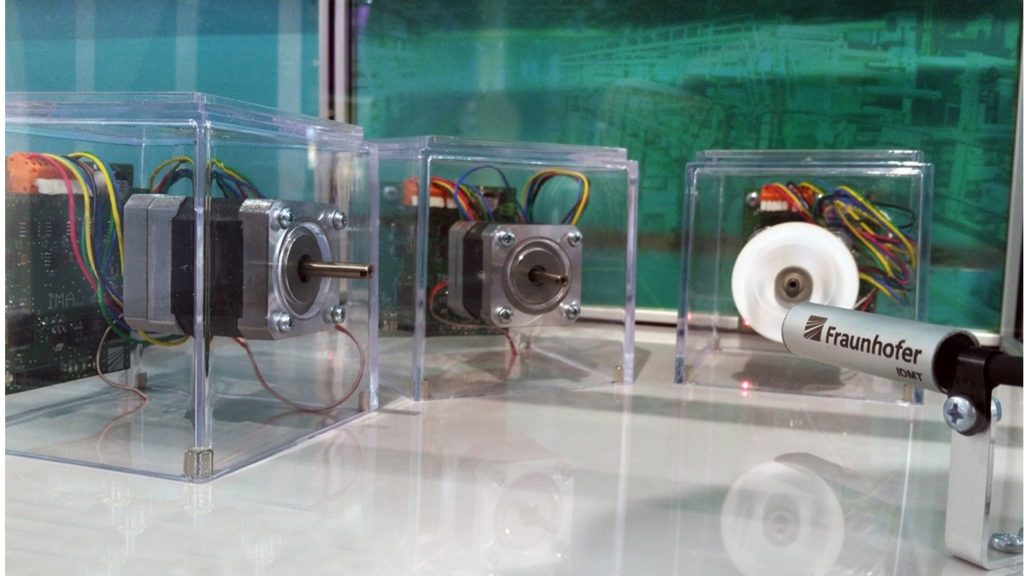

Get an impression of our work and experience our demonstration of “AI-based failure analysis on an electric drive”.

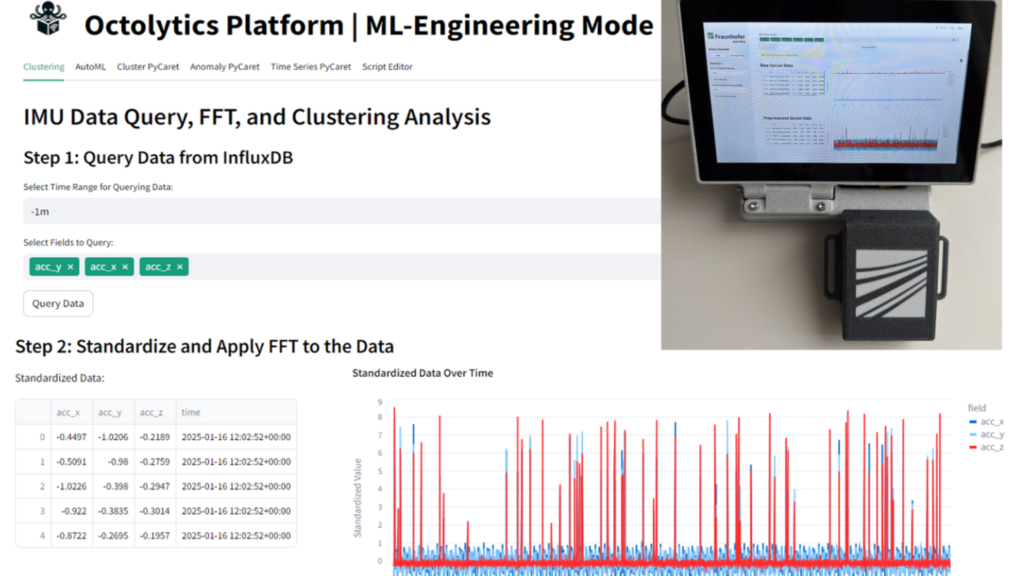

An electric motor with an eccentrically mounted mass attached to its shaft is used to record speed and vibration data. With the help of our specially developed DeepInsights software, our demonstrator can not only record this data, but also analyze it using various algorithms. The result is a live detection of the states: unbalance vs. no unbalance. Furthermore, the predictions of the models, the raw data from the sensors and other analyses are visualized live.

Are you new to the topic of predictive maintenance? During our two-day training course, you will learn about innovative maintenance strategies and, using a checklist, find out how you too can generate competitive advantages for your company through intelligent condition monitoring.

Your contacts at the stand:

Arthur Schimke | Nick Hartmann

Fraunhofer IIS – Division EAS