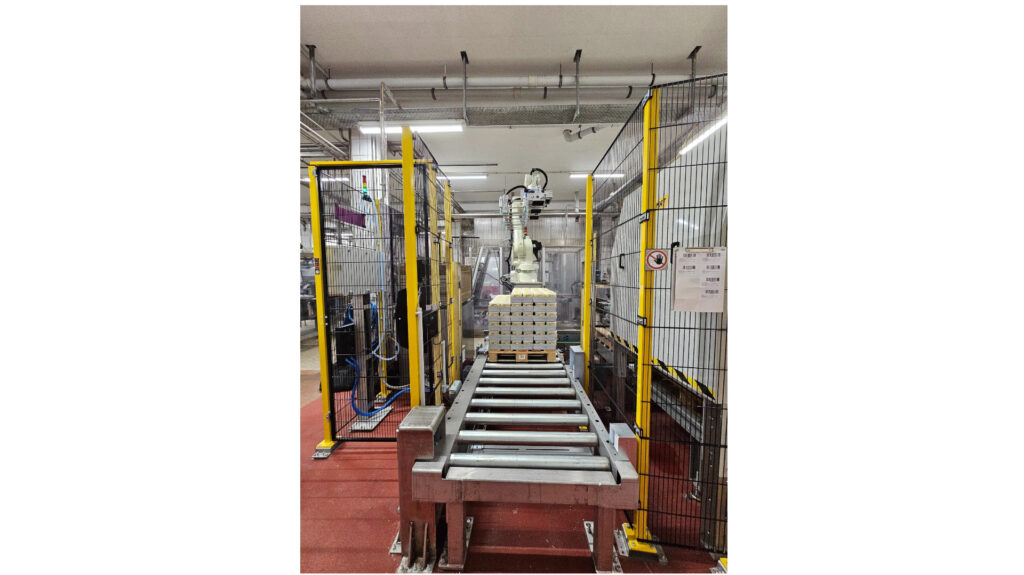

The new robot palletizing system at Wernsing had to be particularly compact, as it was to be integrated into an existing production facility that left little space for the new system. Previously, the coleslaw trays were manually loaded onto pallets. The fully automated palletizing system from de Man requires a footprint of just over 4 x 4 meters. To achieve this, considerable space was saved by, among other things, relocating the magazine with the base and intermediate layers on top of the control cabinet instead of next to it. Empty pallet loading and full pallet removal both take place at the front of the cell, so sufficient maneuvering space is only required on one side. The transfer of pallets from the empty pallet station to the palletizing station is also extremely space-saving thanks to an empty pallet transfer system with a lifting function.

In addition to the compact design and the parallel storage of pallet loading and removal, the specifications for the new de Man system included optional scalability to automate additional lines in the hall, as well as the stainless steel base. The trays containing the products are transported from an upstream carton packer via an existing conveyor system to the de Man palletizing cell. They are initially accumulated in groups of three and then pushed crosswise as a group into the unloading position and centered. The robot – a Kawasaki RD080N – then removes the trays in groups of three using fork grippers and places them on the pallet according to the packing pattern. Hold-down devices ensure safe handling during the dynamic robot movements. During unloading, the robot releases the fastening from above and pulls the forks out from under the cartons. A maximum output of 15 trays/min is achieved. A base layer and up to three intermediate layers are placed on each pallet. Thanks to an integrated vacuum suction gripper, the robot can handle the layers without changing grippers – and therefore without any loss of time.